Rural agricultural operations face unique challenges when it comes to maintaining consistent refrigeration, particularly in remote locations where electrical grid access remains unreliable or non-existent. Gas-powered refrigeration systems have emerged as a robust solution for farmers and agricultural businesses operating beyond the reach of traditional power infrastructure. These systems utilise propane, natural gas, or kerosene as energy sources, providing dependable cooling performance regardless of electrical supply fluctuations.

The agricultural sector’s reliance on proper temperature control cannot be overstated, with post-harvest losses accounting for approximately 25-30% of global food production due to inadequate cooling facilities. Gas-powered refrigeration technology offers a practical alternative that ensures product quality, extends shelf life, and maintains food safety standards in challenging rural environments. This technology becomes particularly crucial for dairy operations, produce storage, livestock care, and seed preservation, where temperature variations can result in significant financial losses.

Absorption refrigeration technology fundamentals in agricultural cooling systems

Absorption refrigeration represents a fundamentally different approach to cooling compared to conventional compressor-driven systems. This technology harnesses heat energy rather than electrical power to drive the refrigeration cycle, making it ideally suited for agricultural applications where consistent electrical supply remains problematic. The system operates on basic thermodynamic principles, utilising the absorption and desorption properties of specific chemical combinations to achieve cooling effects.

Ammonia-water absorption cycle principles for farm applications

The ammonia-water absorption cycle forms the cornerstone of most agricultural gas refrigeration systems. In this process, ammonia serves as the refrigerant whilst water acts as the absorbent, creating a binary fluid system that enables effective heat transfer. The cycle begins when heat from the gas burner drives ammonia vapour from the water solution in the generator, creating a concentrated ammonia vapour that travels to the condenser.

Within the condenser, the ammonia vapour releases heat and transforms into liquid form before entering the evaporator. As the liquid ammonia evaporates in the evaporator, it absorbs heat from the refrigerated space, creating the desired cooling effect. The ammonia vapour then returns to the absorber, where it combines with the weak ammonia solution from the generator, completing the cycle. This continuous process requires no moving parts, making it particularly reliable for demanding agricultural environments.

Heat source requirements: propane, natural gas, and kerosene integration

Agricultural gas refrigeration systems accommodate various fuel types, each offering distinct advantages for different operational scenarios. Propane systems provide exceptional portability and energy density, making them suitable for mobile applications or locations where fuel delivery infrastructure exists. The clean-burning characteristics of propane ensure minimal maintenance requirements whilst delivering consistent heat output for optimal system performance.

Natural gas integration offers cost-effective operation for farms with existing gas pipeline access or biogas production capabilities. Many agricultural operations generate methane through anaerobic digestion of organic waste, creating a renewable fuel source that significantly reduces operational costs. Kerosene-powered systems provide reliability in extremely remote locations where propane delivery proves challenging, though they require more frequent maintenance due to the fuel’s combustion characteristics.

COP efficiency ratings in Gas-Powered agricultural refrigeration units

The Coefficient of Performance (COP) serves as a critical metric for evaluating gas refrigeration system efficiency in agricultural applications. Modern gas-powered agricultural refrigeration units typically achieve COP ratings between 0.6 and 0.8, meaning they produce approximately 0.6 to 0.8 units of cooling energy for every unit of heat energy consumed. Whilst this appears lower than electric refrigeration systems, the comparison becomes favourable when considering the total energy chain efficiency from fuel source to cooling output.

Agricultural operations benefit from understanding that COP ratings vary significantly based on ambient temperature conditions, system load, and maintenance status. Units operating in controlled environments with proper ventilation typically maintain higher COP values throughout their operational lifecycle. Regular calibration and maintenance procedures can improve system efficiency by 10-15%, directly impacting operational costs and environmental performance.

Temperature control mechanisms in absorption cooling systems

Temperature regulation in gas-powered agricultural refrigeration relies on precise control of heat input to the generator section. Modern systems incorporate thermostat-controlled gas valves that modulate burner output based on internal temperature sensors. This modulation ensures consistent cooling performance whilst optimising fuel consumption, particularly important for cost-sensitive agricultural operations.

Advanced systems feature multi-stage control mechanisms that adjust gas flow rates automatically to maintain precise temperature ranges. These controls become particularly valuable for agricultural applications requiring different temperature zones, such as dairy operations needing both refrigeration and freezing capabilities. The thermal mass of agricultural products also influences control strategies, with systems designed to accommodate the slower thermal response characteristics typical of bulk food storage.

Critical cooling applications for rural agricultural operations

Agricultural cooling requirements encompass a diverse range of applications, each presenting unique challenges and specifications. Understanding these applications enables farmers to select appropriate gas refrigeration systems that match their operational needs whilst ensuring product quality and regulatory compliance.

Milk storage and bulk tank cooling in remote dairy farms

Dairy operations represent one of the most demanding agricultural cooling applications, requiring rapid temperature reduction and precise maintenance of milk storage conditions. Gas-powered bulk tank cooling systems must reduce fresh milk temperature from approximately 37°C to 4°C within two hours of collection, as mandated by food safety regulations. This rapid cooling prevents bacterial growth and preserves milk quality during storage periods.

Rural dairy farms particularly benefit from gas refrigeration systems due to their reliability during power outages, which can result in significant milk losses if cooling fails. Modern gas-powered dairy cooling systems incorporate sophisticated control systems that monitor milk temperature continuously, adjusting cooling capacity to maintain optimal storage conditions. The thermal stability provided by gas systems ensures consistent milk quality even during extreme weather conditions that might compromise electrical grid reliability.

Produce preservation: vegetable and fruit cold storage requirements

Fresh produce storage demands precise temperature and humidity control to maintain quality and extend shelf life. Different crops require specific storage conditions, with leafy vegetables typically requiring temperatures between 0-2°C, whilst fruits like apples perform best at 1-4°C with controlled humidity levels. Gas-powered cold storage systems provide the stability needed to maintain these precise conditions over extended periods.

The controlled atmosphere capabilities of advanced gas refrigeration systems enable farmers to modify oxygen and carbon dioxide levels within storage chambers, significantly extending produce shelf life. This capability proves particularly valuable for organic farmers who cannot rely on chemical preservatives to maintain product quality. Gas systems’ ability to operate independently of electrical infrastructure makes them essential for remote farming operations where grid reliability remains questionable.

Livestock medication and vaccine temperature management

Veterinary pharmaceuticals and livestock vaccines require strict temperature control to maintain potency and effectiveness. Most livestock vaccines must remain within 2-8°C temperature ranges, with temperature excursions potentially rendering entire vaccine stocks unusable. Gas-powered pharmaceutical refrigeration provides the reliability necessary to protect these valuable medical supplies in remote agricultural settings.

The financial implications of vaccine spoilage extend beyond replacement costs, as compromised vaccination programmes can result in disease outbreaks affecting entire livestock populations. Gas refrigeration systems’ independence from electrical grid reliability makes them particularly suitable for veterinary applications where consistent cooling represents a critical biosecurity measure. Modern systems incorporate temperature monitoring and alarm systems that alert operators to any deviations from prescribed storage conditions.

Seed storage viability protection through controlled cooling

Seed viability preservation requires precise temperature and humidity control to maintain germination rates and genetic integrity over extended storage periods. Most agricultural seeds benefit from storage temperatures between 0-10°C with relative humidity levels maintained below 50%. Gas-powered seed storage systems provide the consistent environmental conditions necessary to preserve seed quality for multiple growing seasons.

The economic value of quality seed stock makes proper storage conditions essential for agricultural sustainability. Gas refrigeration systems excel in seed storage applications due to their ability to maintain stable conditions without the temperature fluctuations associated with electrical grid irregularities. This stability becomes particularly crucial for hybrid seeds and specialty varieties where replacement costs can significantly impact farm profitability.

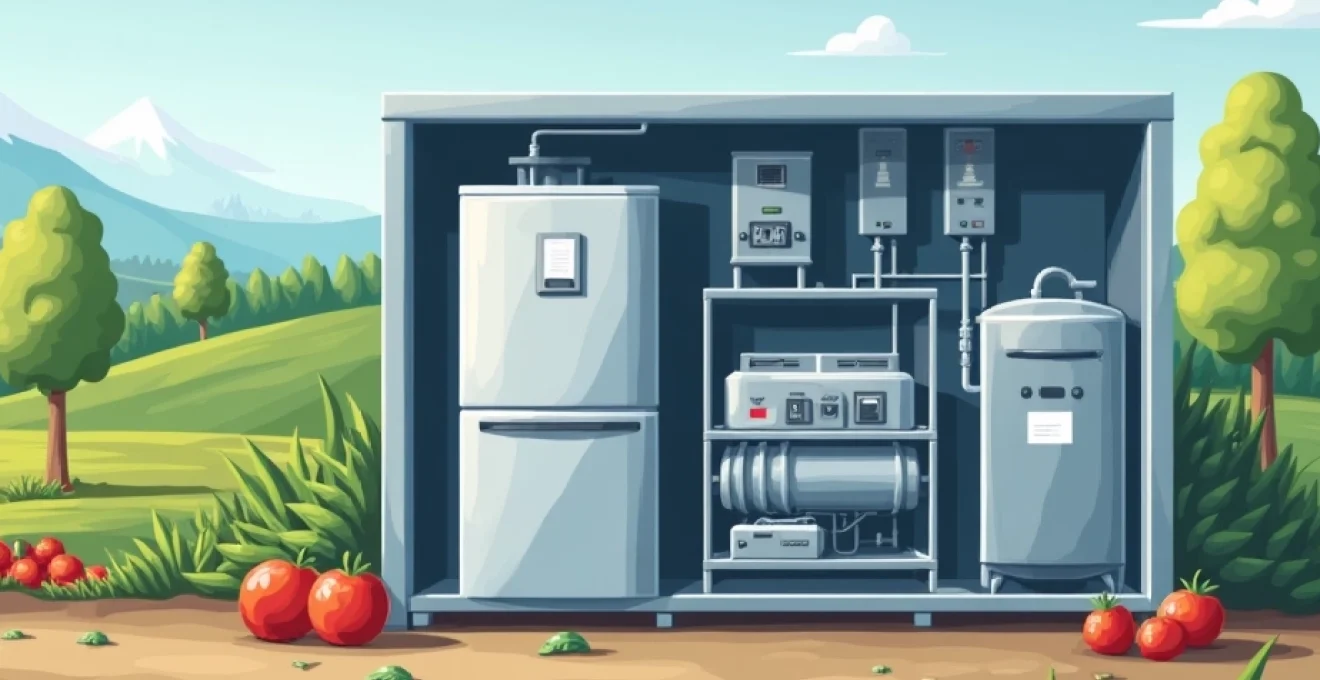

Gas-powered refrigeration equipment selection for farm environments

Selecting appropriate gas refrigeration equipment for agricultural applications requires careful consideration of capacity requirements, environmental conditions, and operational constraints. Agricultural environments present unique challenges including dust exposure, temperature extremes, and limited maintenance access that influence equipment selection decisions. Understanding these factors ensures optimal system performance and longevity in demanding farm conditions.

Capacity sizing represents a critical consideration, as agricultural cooling loads often vary significantly based on harvest schedules, seasonal production patterns, and storage duration requirements. Oversized systems waste fuel and may struggle to maintain precise temperature control, whilst undersized units cannot adequately handle peak cooling demands. Professional load calculations should account for product mass, ambient temperature conditions, insulation effectiveness, and door opening frequency to determine optimal system sizing.

Environmental protection features become essential for agricultural installations, where equipment faces exposure to dust, moisture, corrosive chemicals, and mechanical damage. Systems designed for farm environments incorporate robust housing materials, enhanced filtration systems, and protective components that ensure reliable operation under challenging conditions. Stainless steel construction provides superior corrosion resistance when systems encounter cleaning chemicals or agricultural sprays commonly used in farming operations.

Fuel flexibility often influences equipment selection decisions, particularly for farms with access to multiple fuel sources or biogas production capabilities. Systems capable of operating on various fuel types provide operational flexibility and cost optimisation opportunities. Many modern agricultural gas refrigeration units feature convertible burner assemblies that accommodate propane, natural gas, or biogas with minimal modification requirements.

Maintenance accessibility significantly impacts long-term operational success, as agricultural systems often operate in remote locations with limited technical support availability. Equipment designs incorporating accessible service points, simplified maintenance procedures, and robust diagnostic capabilities reduce downtime and maintenance costs. Systems featuring modular component designs enable farmers to perform routine maintenance tasks without requiring specialised technical expertise.

The reliability of gas-powered refrigeration systems in agricultural environments stems from their mechanical simplicity and independence from electrical infrastructure, making them ideal solutions for remote farming operations where consistent cooling performance directly impacts profitability and food safety compliance.

Installation challenges and infrastructure requirements in Off-Grid locations

Installing gas refrigeration systems in remote agricultural locations presents unique challenges that require careful planning and specialised expertise. The absence of conventional utilities and limited access to technical support services demands robust installation approaches that ensure long-term operational reliability. Understanding these installation requirements enables agricultural operators to prepare adequately for successful system deployment.

Propane supply chain logistics for remote agricultural sites

Establishing reliable propane supply chains for remote agricultural installations requires comprehensive logistics planning to ensure continuous fuel availability during critical operational periods. Tank sizing calculations must account for consumption rates, delivery frequency constraints, and emergency reserve requirements to prevent cooling system failures during peak demand periods. Most agricultural operations benefit from installing multiple smaller tanks rather than single large storage units, providing redundancy and flexible fuel management options.

Delivery infrastructure development often necessitates road improvements or alternative transport arrangements to accommodate fuel delivery vehicles. Remote locations may require specialised delivery equipment or alternative fuel transport methods such as helicopter delivery for extremely isolated sites. Establishing fuel storage and handling procedures that comply with safety regulations whilst ensuring convenient access for routine system operation becomes essential for successful installations.

Ventilation requirements for safe gas refrigerator operation

Proper ventilation design ensures safe operation of gas refrigeration systems whilst maintaining optimal performance characteristics. Combustion air supply and exhaust gas removal require carefully engineered ventilation systems that accommodate seasonal weather variations and prevent carbon monoxide accumulation. Agricultural installations often require enhanced ventilation capacities due to dusty environments that can compromise air intake and exhaust pathways.

Ventilation system design must account for prevailing wind patterns, seasonal weather conditions, and building orientation to ensure reliable air circulation under all operational scenarios. Natural draft ventilation systems provide reliable operation without requiring electrical power, though they require careful design to ensure adequate air movement during calm weather conditions. Mechanical ventilation systems offer superior control but require backup power sources to maintain safety during electrical outages.

Foundation and structural considerations for Heavy-Duty units

Agricultural gas refrigeration systems often require substantial foundation support due to their robust construction and the additional weight of fuel storage systems. Foundation designs must accommodate frost protection requirements, drainage considerations, and seismic loads where applicable. Proper foundation preparation prevents system misalignment and ensures optimal door sealing performance that directly impacts cooling efficiency.

Structural considerations extend beyond foundation requirements to include adequate clearance for service access, fuel line routing, and ventilation system installation. Agricultural environments often require additional structural protection to prevent damage from farming equipment, livestock, or extreme weather conditions. Installation locations should provide convenient access for maintenance activities whilst ensuring protection from operational hazards present in active farming environments.

Electrical integration for hybrid Gas-Electric cooling systems

Hybrid systems combining gas refrigeration with electrical components require careful electrical integration to ensure reliable operation and safety compliance. Control systems, lighting, and monitoring equipment typically operate on electrical power even when the primary cooling function utilises gas energy. Solar power integration or small generator systems often provide the electrical power needed for these auxiliary systems in off-grid installations.

Electrical system design must accommodate the unique requirements of agricultural environments, including surge protection, moisture resistance, and electromagnetic interference from farming equipment. Battery backup systems ensure continued operation of critical monitoring and safety systems during power outages, preventing system damage or safety hazards. Proper grounding and electrical protection systems become essential for installations in agricultural environments where electrical faults could create serious safety risks.

Maintenance protocols and troubleshooting for agricultural gas refrigeration

Effective maintenance protocols ensure optimal performance and longevity of gas refrigeration systems in demanding agricultural environments. The remote nature of many agricultural installations necessitates comprehensive maintenance approaches that farmers can implement with basic technical skills. Understanding these maintenance requirements enables agricultural operators to minimise downtime and extend system operational life.

Burner assembly cleaning and gas flow calibration procedures

Burner assembly maintenance represents a critical aspect of gas refrigeration system care, directly impacting fuel efficiency and cooling performance. Regular cleaning procedures remove dust, debris, and combustion deposits that accumulate during normal operation in agricultural environments. Cleaning protocols should address burner ports, air mixing chambers, and ignition components using appropriate tools and cleaning agents that maintain component integrity.

Gas flow calibration ensures optimal combustion efficiency and prevents incomplete burning that reduces system performance and creates safety hazards. Calibration procedures involve adjusting primary air openings, checking gas pressure settings, and verifying flame characteristics against manufacturer specifications. Agricultural operators should maintain calibration records and perform adjustments according to seasonal operating conditions and fuel quality variations commonly encountered in rural areas.

Absorption unit component inspection and replacement schedules

Absorption unit components require periodic inspection to identify wear patterns and potential failure points before they impact system operation. Generator section inspection focuses on heat exchanger surfaces, solution pumps, and internal piping for signs of corrosion or blockage. Condenser and evaporator sections need regular cleaning to maintain heat transfer efficiency, particularly important in dusty agricultural environments where debris accumulation affects performance.

Replacement scheduling for absorption system components depends on operating conditions, fuel quality, and maintenance quality throughout the system lifecycle. Critical components such as solution pumps, control valves, and heat exchangers typically require replacement every 5-10 years under normal agricultural operating conditions. Maintaining spare parts inventory for critical components reduces downtime during harvest periods when cooling system failures create maximum financial impact.

Flue system maintenance and carbon monoxide safety monitoring

Flue system maintenance ensures safe exhaust gas removal and prevents carbon monoxide accumulation that poses serious health and safety risks. Regular inspection procedures address flue pipe integrity, draft hood operation, and exhaust termination clearances. Agricultural installations often require enhanced flue protection due to exposure to farming equipment, weather extremes, and potential impact damage from operational activities.

Carbon monoxide monitoring systems provide essential safety protection for agricultural gas refrigeration installations, particularly in enclosed or semi-enclosed spaces. Modern monitoring systems feature audible and visual alarms that alert operators to dangerous gas concentrations before they reach hazardous levels. Testing procedures should verify monitor functionality and calibration accuracy according to manufacturer recommendations and local safety regulations.

Refrigerant level assessment and system leak detection methods

Refrigerant level assessment in absorption systems requires specialised techniques due to the sealed nature of the absorption circuit and the binary fluid system complexity. Visual inspection methods focus on external signs of refrigerant leaks, including white crystalline deposits around fittings and discoloration of system components. Performance monitoring provides indirect assessment of refrigerant levels through cooling capacity measurements and temperature differential analysis.

Leak detection methods for agricultural gas refrigeration systems accommodate the unique characteristics of ammonia-water solutions and the challenging environments where these systems operate. Electronic leak detectors specifically designed for ammonia detection provide accurate identification of small leaks before they impact system performance. Regular pressure testing and system evacuation procedures help identify internal leaks that may not be visible through external inspection methods.

Proactive maintenance approaches significantly extend gas refrigeration system operational life whilst reducing the risk of catastrophic failures during critical agricultural

periods, ensuring continuous operation when agricultural productivity depends most heavily on reliable cooling systems.

Economic viability analysis: gas refrigeration versus grid-dependent alternatives

The economic justification for gas-powered refrigeration in agricultural operations extends beyond initial capital costs to encompass total cost of ownership throughout the system lifecycle. Rural agricultural operations must evaluate multiple financial factors including infrastructure development costs, operational expenses, maintenance requirements, and opportunity costs associated with cooling system failures. Understanding these economic dynamics enables farmers to make informed decisions about cooling technology investments that align with their operational requirements and financial constraints.

Initial capital investment comparisons reveal that gas refrigeration systems typically require higher upfront costs than basic electric units, but this differential narrows significantly when grid extension costs are factored into remote installation scenarios. Electrical infrastructure development for remote agricultural sites often exceeds $10,000-50,000 per kilometer, making gas systems economically attractive for locations more than 2-3 kilometers from existing power lines. Additionally, transformer upgrades and electrical service connections add substantial costs that gas systems avoid entirely.

Operational cost analysis demonstrates significant advantages for gas refrigeration in regions with high electricity rates or unreliable grid service. Propane costs typically range from $0.08-0.15 per kWh equivalent, comparing favorably to commercial electricity rates that often exceed $0.12-0.25 per kWh in rural areas. Natural gas operations achieve even lower operational costs, particularly for farms with biogas production capabilities that can provide renewable fuel sources at minimal marginal cost.

Reliability benefits translate directly into economic value through reduced product losses and enhanced operational flexibility. Agricultural operations report that grid-dependent cooling systems experience an average of 15-25 hours of downtime annually due to power outages, potentially resulting in thousands of dollars in product losses during critical periods. Gas refrigeration systems’ independence from electrical infrastructure eliminates these weather-related and grid-maintenance outages that frequently impact rural electrical service.

Maintenance cost considerations favor gas systems in remote agricultural applications due to their mechanical simplicity and reduced dependence on specialized electronic components that require expert repair services. Electric refrigeration systems increasingly incorporate sophisticated control systems and variable-speed compressors that demand specialized diagnostic equipment and replacement parts often unavailable in rural service areas. Gas system maintenance typically involves routine cleaning and calibration procedures that farm personnel can perform with basic tools and training.

Insurance implications also factor into economic viability assessments, as many agricultural insurance policies provide premium reductions for facilities with backup cooling systems or non-grid-dependent refrigeration. These premium savings, combined with reduced business interruption risks, contribute to the overall economic attractiveness of gas refrigeration investments. Some insurance providers specifically recognize gas refrigeration systems as risk mitigation measures for temperature-sensitive agricultural operations.

Return on investment calculations for gas refrigeration systems typically show payback periods of 3-7 years for agricultural applications, depending on electricity costs, system utilization rates, and product value density. High-value products such as organic produce, dairy products, or specialty crops generate faster payback periods due to the significant financial impact of cooling system failures. The payback period shortens further when factoring in avoided electrical infrastructure costs and improved operational reliability benefits.

Financing considerations affect economic viability, with various agricultural lending programs and equipment financing options available for gas refrigeration installations. Many equipment manufacturers offer lease-purchase arrangements that align payment schedules with agricultural cash flow patterns, reducing the financial impact of initial capital requirements. Government incentive programs for energy-efficient agricultural equipment sometimes include gas refrigeration systems, particularly those meeting specific efficiency standards or incorporating renewable fuel capabilities.

Long-term economic sustainability depends on fuel price stability and availability, factors that vary significantly by geographic region and market conditions. Propane prices generally exhibit less volatility than electricity rates, providing more predictable operational cost structures for agricultural budgeting purposes. Farms with renewable gas production capabilities achieve the greatest long-term economic benefits through fuel cost stability and potential revenue generation from excess biogas production.

The economic analysis ultimately demonstrates that gas-powered refrigeration systems provide compelling value propositions for remote agricultural operations, particularly when evaluated on a total cost of ownership basis rather than initial purchase price alone. These systems excel in applications where electrical infrastructure limitations, reliability requirements, or operational flexibility demands justify the investment in alternative cooling technology that ensures stable agricultural operations regardless of external utility service limitations.