Modern manufacturing demands precision that pushes the boundaries of what traditional machining methods can achieve. As industries like aerospace, automotive, and medical devices require increasingly complex components with tighter tolerances, manufacturers are turning to advanced cooling technologies to meet these exacting standards. Liquid nitrogen cooling represents a transformative approach that addresses the fundamental challenge of heat management in high-speed CNC machining operations.

The extreme temperatures generated during cutting operations can severely compromise both tool performance and workpiece quality. Traditional flood coolants, while effective to a degree, often fall short when dealing with difficult-to-machine materials like titanium alloys, Inconel, and hardened steels. Cryogenic cooling using liquid nitrogen offers a revolutionary solution, delivering cooling capabilities that extend far beyond conventional methods whilst simultaneously improving environmental sustainability.

Cryogenic cooling fundamentals in CNC machining operations

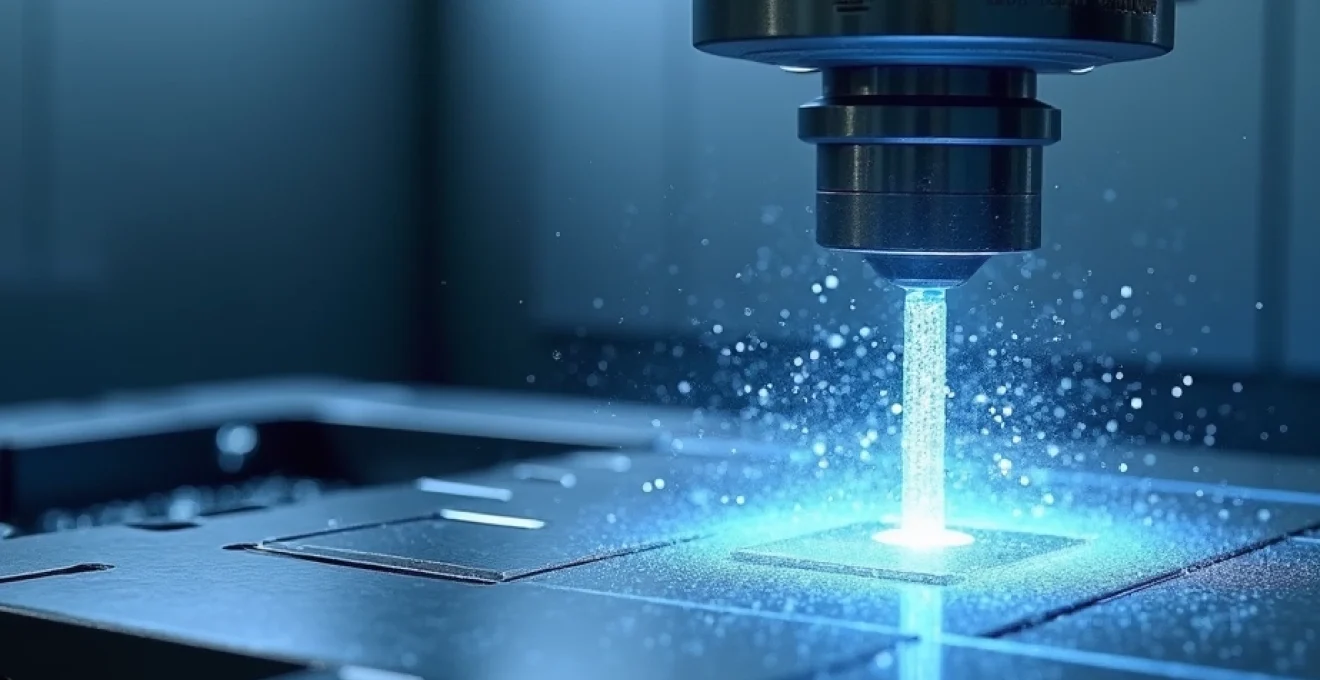

Cryogenic cooling in machining operations harnesses the extreme low temperatures of liquefied gases, primarily nitrogen, to create optimal cutting conditions. This technology transforms the thermal dynamics of the cutting zone, enabling manufacturers to achieve previously unattainable levels of precision and efficiency. The fundamental principle relies on the dramatic temperature differential between the cryogenic coolant and the heated cutting interface, creating superior heat extraction capabilities.

Liquid nitrogen properties and phase change mechanisms

Liquid nitrogen exists at approximately -196°C (-321°F) at atmospheric pressure, providing an enormous temperature differential compared to conventional coolants operating at ambient temperatures. This cryogenic medium undergoes rapid phase changes when it contacts the heated cutting zone, transitioning from liquid to gas whilst absorbing substantial amounts of latent heat. The evaporation process creates a protective gas cushion at the tool-chip interface, reducing friction and preventing tool adhesion.

The phase change mechanism occurs in multiple stages as the nitrogen encounters different temperature zones within the cutting area. Initially, the liquid nitrogen maintains its phase when directed toward the cutting zone, but as it approaches the high-temperature regions, nucleate boiling begins. This boiling process extracts heat at rates significantly higher than single-phase convective cooling, making it exceptionally effective for managing thermal loads in high-speed machining operations.

Heat transfer coefficients in nitrogen cooling vs traditional flood coolants

Research demonstrates that cryogenic nitrogen cooling achieves heat transfer coefficients ranging from 20,000 to 50,000 W/m²K, dramatically exceeding the 2,000-3,000 W/m²K typically achieved with conventional flood coolants. This represents a fifteen to twenty-fold improvement in heat extraction capability, directly translating to lower cutting temperatures and reduced thermal stress on both tools and workpieces.

The superior heat transfer performance results from several factors working in combination. The extreme temperature differential creates a powerful driving force for heat transfer, whilst the rapid evaporation of liquid nitrogen generates turbulent mixing that enhances convective heat transfer. Additionally, the formation of a thin liquid film at the stagnation point provides excellent thermal contact between the coolant and the heated surfaces.

Cryogenic temperature ranges and optimal flow rates for precision machining

Optimal cryogenic cooling requires careful consideration of flow rates, typically ranging from 0.5 to 2.0 litres per minute depending on the machining operation and material being processed. Lower flow rates around 0.5 L/min prove effective for finishing operations where surface quality takes precedence, whilst higher flow rates up to 2.0 L/min become necessary for aggressive roughing operations on difficult-to-machine materials.

The temperature gradient across the cutting zone varies significantly with flow rate and nozzle positioning. Studies indicate that effective cooling penetration extends approximately five nozzle diameters from the impingement point, creating a cooling zone that must be strategically positioned to maximise tool life and surface quality. Temperature measurements show reductions of 15-20% compared to dry machining conditions, with even greater benefits observed in high-speed applications.

Boiling point dynamics and vapour pressure effects on cutting zones

The boiling dynamics of liquid nitrogen in the cutting zone create complex multiphase flow patterns that significantly influence cooling effectiveness. As the nitrogen encounters heated surfaces, film boiling occurs initially, followed by nucleate boiling as surface temperatures decrease. This transition between boiling regimes affects the heat transfer coefficient, with nucleate boiling providing superior cooling performance.

Vapour pressure effects become particularly important in confined spaces, such as deep hole drilling operations. The rapid expansion of nitrogen gas creates positive pressure that assists with chip evacuation, simultaneously providing cooling and mechanical cleaning of the cutting zone. This dual action proves especially beneficial when machining materials prone to work hardening or galling.

Tool wear reduction through nitrogen cooling systems

The implementation of nitrogen cooling systems delivers measurable improvements in tool wear characteristics across all major tool categories. By maintaining lower and more stable cutting temperatures, cryogenic cooling minimises the thermal and chemical wear mechanisms that typically limit tool life in conventional machining operations. The protective nitrogen atmosphere also reduces oxidation and chemical reactions that contribute to crater wear and edge degradation.

Carbide insert performance with kennametal KC5010 in cryogenic environments

Carbide inserts demonstrate exceptional performance improvements under cryogenic cooling conditions, with tool life extensions of 40-60% commonly observed. The Kennametal KC5010 grade, specifically designed for steel machining, shows remarkable resistance to thermal shocking when subjected to liquid nitrogen cooling. The rapid cooling prevents the formation of built-up edge whilst maintaining the carbide’s hardness at elevated cutting speeds.

Temperature cycling effects, often a concern with dramatic cooling, prove minimal due to the uniform cooling provided by properly designed nitrogen delivery systems. The consistent temperature control prevents thermal fatigue cracking whilst simultaneously reducing the diffusion wear that typically limits carbide performance in high-temperature applications. Flank wear progression slows dramatically, extending the useful cutting life and improving surface finish consistency throughout the tool’s operational period.

HSS tool life extension using sandvik coromant nitrogen delivery systems

High-speed steel tools benefit significantly from cryogenic cooling, particularly in applications where their toughness advantages outweigh the hardness limitations compared to carbide alternatives. Sandvik Coromant’s nitrogen delivery systems demonstrate the potential for HSS tool life improvements of 30-50% when properly implemented. The cooling effect maintains the steel’s tempered hardness whilst reducing the thermal softening that typically limits cutting speeds.

The protection against thermal degradation becomes particularly important in interrupted cutting operations where HSS tools experience thermal cycling. Nitrogen cooling provides rapid heat extraction during the cutting phase whilst the gas atmosphere protects against oxidation during the non-cutting portions of the cycle. This protection mechanism proves crucial for maintaining edge sharpness and preventing thermal cracking in demanding applications.

Ceramic cutting tool thermal shock prevention in titanium machining

Ceramic cutting tools face unique challenges in titanium machining due to the material’s low thermal conductivity and tendency to generate high cutting temperatures.

Cryogenic cooling addresses the thermal shock susceptibility of ceramic tools by providing controlled cooling that prevents rapid temperature fluctuations whilst maintaining the ceramic’s inherent hardness advantages.

This controlled thermal environment enables ceramic tools to achieve their full potential in titanium applications.

The nitrogen atmosphere also prevents the chemical reactions between ceramic tools and reactive titanium that can lead to rapid tool degradation. By maintaining an inert environment around the cutting edge, cryogenic cooling extends ceramic tool life by 25-40% whilst enabling higher cutting speeds that would otherwise result in catastrophic tool failure. The improved thermal management also reduces the tendency for titanium to work harden, creating better cutting conditions throughout the operation.

PCD diamond tool longevity under cryogenic cooling conditions

Polycrystalline diamond (PCD) tools represent the pinnacle of cutting tool technology for non-ferrous applications, and cryogenic cooling enhances their already impressive performance characteristics. The extreme hardness of PCD tools combined with the thermal management provided by nitrogen cooling creates ideal conditions for precision machining of aluminium alloys and composites. Tool life improvements of 20-35% are commonly achieved whilst maintaining exceptional surface finish quality.

The thermal protection becomes particularly important when machining abrasive materials or composites where thermal damage can compromise the diamond crystal structure. Nitrogen cooling maintains the PCD cutting edge below critical temperatures whilst the inert atmosphere prevents oxidation of the diamond structure. This protection mechanism proves essential for maintaining the mirror-like surface finishes that PCD tools are renowned for producing.

Machining precision enhancement mechanisms

Precision enhancement through nitrogen cooling operates through multiple interconnected mechanisms that address the fundamental causes of dimensional and surface quality deviations. The thermal stability provided by cryogenic cooling eliminates many of the variables that compromise machining accuracy, creating more predictable and repeatable results. Understanding these mechanisms enables manufacturers to optimise their processes for maximum precision benefits.

Thermal distortion minimisation in aluminium 7075-T6 components

Aluminium 7075-T6 components are particularly susceptible to thermal distortion due to the material’s high coefficient of thermal expansion and excellent thermal conductivity. Conventional cooling methods often struggle to manage the heat generated during high-speed aluminium machining, leading to dimensional variations and poor surface finish. Cryogenic nitrogen cooling addresses these challenges by maintaining workpiece temperatures close to ambient levels throughout the machining process.

The rapid heat extraction provided by liquid nitrogen prevents the thermal gradients that cause workpiece distortion, enabling the production of components with tolerances as tight as ±0.005mm. This level of precision proves particularly valuable in aerospace applications where dimensional accuracy directly impacts component performance and safety. The consistent cooling also eliminates the thermal cycling that can cause stress relief and dimensional changes in heat-treated aluminium alloys.

Surface roughness improvements in inconel 718 aerospace parts

Inconel 718 presents significant machining challenges due to its work hardening tendency and poor thermal conductivity, often resulting in surface roughness values that require secondary finishing operations. Cryogenic cooling transforms the machinability of this superalloy by preventing work hardening whilst maintaining optimal cutting conditions. Surface roughness improvements of 30-50% are routinely achieved, with Ra values consistently below 0.8 micrometres.

The improved surface integrity extends beyond roughness measurements to include reduced residual stress and improved metallurgical structure.

The controlled thermal environment prevents the formation of white layers and other thermal damage whilst maintaining the beneficial effects of controlled plastic deformation in the surface region.

This combination of factors creates surfaces with enhanced fatigue resistance and corrosion performance, critical requirements for aerospace applications.

Dimensional accuracy control during High-Speed milling operations

High-speed milling operations generate substantial heat that can cause dimensional errors through thermal expansion of both the workpiece and machine structure. Nitrogen cooling provides precise thermal control that maintains dimensional stability throughout extended machining cycles. The consistent cooling prevents the thermal gradients that cause machine tool growth and workpiece distortion, enabling the maintenance of tight tolerances even at elevated cutting speeds.

Process monitoring data indicates that dimensional variation decreases by 40-60% when cryogenic cooling is properly implemented in high-speed milling operations. The improved thermal stability also enables the use of higher cutting parameters without compromising accuracy, resulting in both improved productivity and enhanced precision. Machine tool thermal compensation systems work more effectively when combined with workpiece cooling, creating a synergistic effect that maximises dimensional control.

Residual stress reduction in hardened steel workpieces

Residual stress generation in hardened steel components represents a critical concern that affects both dimensional stability and service performance. Traditional machining methods often induce high tensile residual stresses that can lead to distortion and reduced fatigue life. Cryogenic cooling addresses this challenge by controlling the thermal and mechanical aspects of the cutting process that generate residual stresses.

The controlled cooling provided by liquid nitrogen creates beneficial compressive residual stresses in the surface layers whilst minimising the depth of the heat-affected zone. This stress distribution proves particularly advantageous for components subjected to cyclic loading, where surface compressive stresses enhance fatigue resistance. Studies demonstrate residual stress improvements of 25-40% compared to conventional cooling methods, with corresponding improvements in component service life and dimensional stability.

Industrial implementation of nitrogen cooling technology

The successful implementation of nitrogen cooling technology requires careful consideration of system design, infrastructure requirements, and operational protocols. Modern cryogenic systems integrate seamlessly with existing CNC machine tools through retrofitable nozzle systems and automated control interfaces. The technology has evolved from experimental applications to production-ready systems that deliver consistent performance across diverse manufacturing environments.

Integration strategies vary depending on the specific machining application and production requirements. Single-nozzle systems prove effective for turning operations where cooling can be directed precisely at the cutting zone, whilst multi-nozzle arrangements become necessary for milling applications requiring comprehensive cooling coverage. The delivery system design must account for nozzle positioning, flow rates, and timing control to maximise cooling effectiveness whilst minimising nitrogen consumption.

Production implementation requires consideration of nitrogen supply logistics, including on-site storage capacity and delivery scheduling. Most manufacturing facilities opt for bulk liquid nitrogen storage systems with automated monitoring and reordering capabilities. The infrastructure investment typically recovers within 12-18 months through improved productivity and reduced tooling costs, making it an attractive option for medium to high-volume production environments.

Operator training represents a crucial element of successful implementation, focusing on safety procedures, system operation, and troubleshooting protocols. The technology requires minimal day-to-day intervention once properly configured, but operators must understand the system parameters and safety requirements. Process monitoring systems provide real-time feedback on cooling effectiveness and nitrogen consumption, enabling continuous optimisation of cutting parameters and cooling delivery.

Cost-benefit analysis and ROI calculations for cryogenic machining systems

Economic analysis of cryogenic machining systems reveals compelling financial benefits that extend well beyond the initial equipment investment. The primary cost components include system acquisition, installation, nitrogen supply, and ongoing maintenance, whilst the benefits encompass reduced tooling costs, improved productivity, enhanced quality, and reduced environmental compliance costs. Comprehensive ROI calculations typically demonstrate payback periods ranging from 8-24 months depending on application intensity and material types.

Tooling cost reductions represent the most immediate and measurable benefit, with tool life improvements of 30-60% translating directly to reduced cutting tool expenditure. For facilities processing difficult-to-machine materials like titanium or Inconel, annual tooling cost savings of £50,000-£200,000 are commonly achieved. These savings become particularly significant when considering the costs of premium cutting tools required for aerospace and medical applications.

Productivity improvements arise from multiple factors including higher cutting speeds, reduced downtime for tool changes, and improved first-pass quality that eliminates rework requirements.

Manufacturing facilities report productivity gains of 15-35% when cryogenic cooling is properly implemented, with the highest improvements observed in applications involving difficult-to-machine materials or tight tolerance requirements.

These productivity enhancements enable manufacturers to meet increased demand without additional capital equipment investments.

Nitrogen consumption costs vary significantly with application parameters but typically range from £2-£8 per hour of machining time. When compared to the costs of conventional coolant purchase, disposal, and environmental compliance, cryogenic systems often prove cost-neutral or advantageous from an operating expense perspective. The elimination of coolant disposal costs and reduced environmental compliance burden provide additional economic benefits that strengthen the overall business case.

Quality improvements contribute to ROI through reduced scrap rates, elimination of secondary finishing operations, and enhanced customer satisfaction. Components machined with cryogenic cooling demonstrate improved dimensional accuracy, surface finish, and metallurgical properties that often command premium pricing in high-value markets. The ability to machine components to final specifications without secondary operations provides both cost savings and competitive advantages.

Safety protocols and equipment requirements for liquid nitrogen handling

Safe operation of liquid nitrogen cooling systems requires comprehensive safety protocols and appropriate equipment to manage the unique hazards associated with cryogenic fluids. The primary risks include cold burns from direct contact, asphyxiation from nitrogen gas displacement of breathing air, and pressure-related hazards from rapid evaporation in confined spaces. Proper training, equipment selection, and operational procedures effectively mitigate these risks whilst enabling safe system operation.

Personal protective equipment requirements include insulated gloves, safety glasses, and appropriate footwear when working near cryogenic systems. Facilities must maintain adequate ventilation to prevent nitrogen gas accumulation, with oxygen monitoring systems recommended in areas where significant nitrogen usage occurs. Emergency procedures should address liquid nitrogen spills, equipment malfunctions, and personnel exposure incidents, with clear evacuation routes and communication protocols established.

Equipment specifications for cryogenic machining systems must meet relevant safety standards including pressure vessel regulations, electrical classification requirements for potentially explosive atmospheres, and material compatibility standards for low-temperature service. Nitrogen delivery systems require proper insulation

to prevent heat loss and pressure relief valves to manage thermal expansion during system warm-up periods. Installation must consider proximity to electrical equipment, accessibility for maintenance, and integration with existing machine tool systems without compromising safety or performance.

Storage and handling protocols require designated areas with appropriate ventilation, spill containment, and access controls to prevent unauthorised personnel from entering hazardous zones. Regular inspection schedules must address valve functionality, line integrity, and insulation condition to ensure continued safe operation. Emergency shutdown systems should provide immediate nitrogen flow cessation in case of equipment malfunction or personnel emergency, with clear visual and audible indicators of system status at all times.

Regulatory compliance encompasses various standards including OSHA requirements for hazardous materials handling, local fire codes for cryogenic storage, and industry-specific regulations for manufacturing environments. Documentation requirements include safety data sheets, operator training records, and maintenance logs that demonstrate ongoing compliance with applicable regulations. Regular safety audits and risk assessments help identify potential improvements and ensure continued adherence to best practices as technology and regulations evolve.

Training programmes must address both technical operation and emergency response procedures, with refresher courses scheduled annually or when personnel changes occur. Simulation exercises help operators develop confidence in handling emergency situations whilst reinforcing proper operational procedures. The investment in comprehensive safety protocols and training pays dividends through reduced insurance costs, improved regulatory compliance, and most importantly, protection of personnel and facilities from preventable accidents.